Bengaluru, 26th July, 2017: TUV Rheinland India, a subsidiary of TUV Rheinland Group, Germany, a worldwide leader in Testing, Training, Inspection, Consulting & Certification, announced that it has achieved another milestone by adding the long range testing & certification activities for the Indian market. With the introduction of CMW 500 signalling unit and available infrastructure of its 10m anechoic chamber, TUV Rheinland India can now offer, complete testing & certification services for 2G, 3G, and 4G cellular etc. for various applications.

“We are extremely pleased that this is one of the unique services offered amongst our competitors and the first to be offered in TR – Group companies”, said Thomas Fuhrmann, Managing Director, TUV Rheinland India. “With this facility & necessary accreditations like A2LA, ISO 17025, FCC & IC in place, we can actively cover complete short range & long range testing & certification activities from India, which covers the complete gambit of regulatory testing services.”

India being one of the fastest growing markets in wireless industry globally, it is estimated that 20 billion connected wireless devices are in use for various sectors of Internet of Things(IoT), be it smart city, smart grid, home automation, automotive wireless, mobile communication, M2M (machine to machine communication), cyber security and so on. Also with India looking forward to make its manufacturing & industries sectors smarter, Industry 4.0 roadmap shall play a major role in automating and secure data exchange in manufacturing technologies.

“With growing demand of wireless technology & increase in the manufacture base for mobile phones, tablet PC, PDAs and various life style products, testing & certification of these devices has become a necessity” said Kalyan Varma, Vice President Products, TUV Rheinland India.“TUV Rheinland India is now completely geared up to offer the testing & certification for complete wireless technologies, while championing the short range wireless testing & certification activities for Wi-Fi, Bluetooth, ZigBee, RFID etc. for various applications designed for world-wide & regional based Industrial, Scientific and Medical (ISM)/Unlicensed bands with all modulations techniques supported as well.”

With survey reports that suggests, India is going to need a minimum of 8 – 10 billion communication modules to be integrated into smart sensors and controllers, and another 10 – 50 million gateways that need to operate and maintain the Nation Wide Critical Infrastructure, with already a staggering 40 million plus telecommunication & long range customer equipment being deployed. The time was right for TUV Rheinland India to scale up their services to cater to the biggest regulatory market.

The services in 2012-13 were initially semi-furnished with non-availability of a long range network simulator to provide the complete in-house test services. In 2014-15, TUV Rheinland India worked together with Standard-Body (3GPP, ETSI, FCC, ILAC, IEEE, etc.) & it members to understand the needs and list of critical components to put-up a very well defined and holistic test suite to emerge as the premium long-range wireless test provider.

“The exploding market for telecommunication products since 1934 has created technological advances that no one could have imagined. By upgrading our testing labs in India, TUV Rheinland has met and continues to meet the demand by industry leaders worldwide for electromagnetic compatibility (EMC) tests as per global industry requirements.” added Kalyan Varma.

The post Wireless Testing & Certification For Long Range Devices appeared first on Electronics For You.

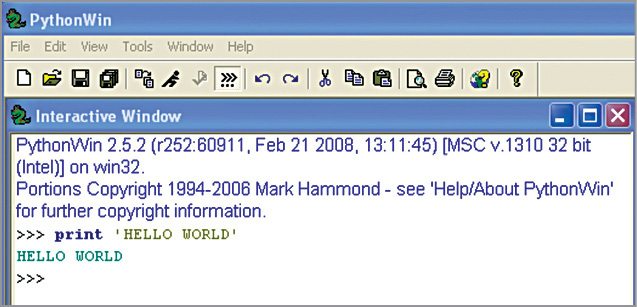

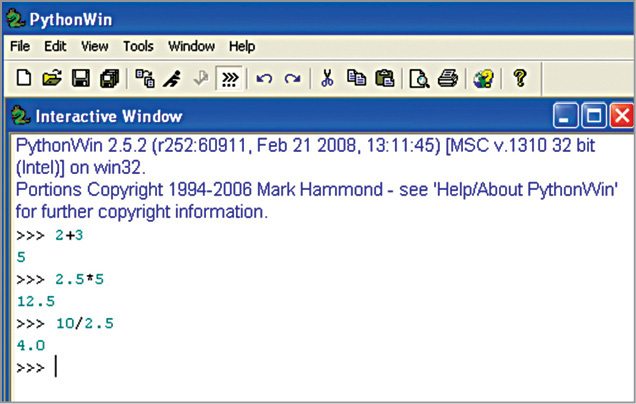

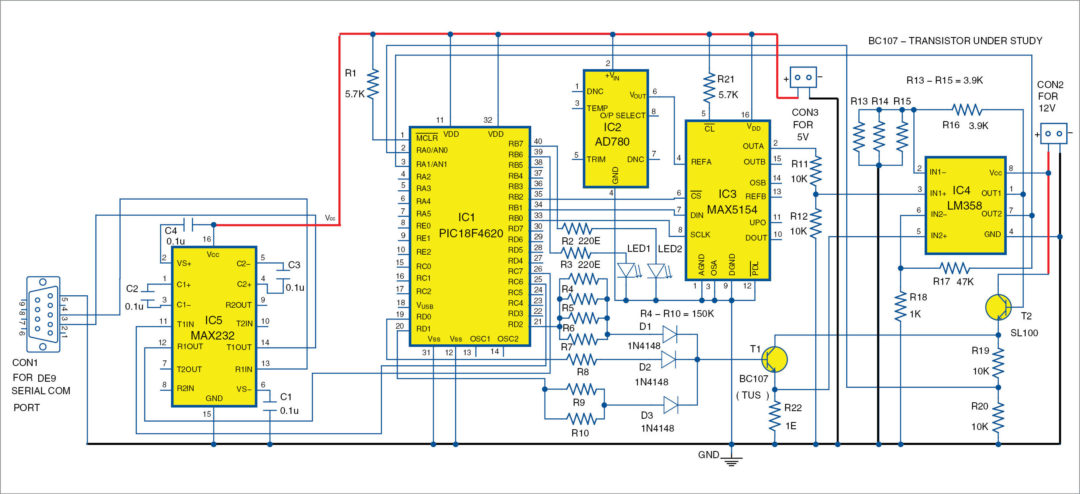

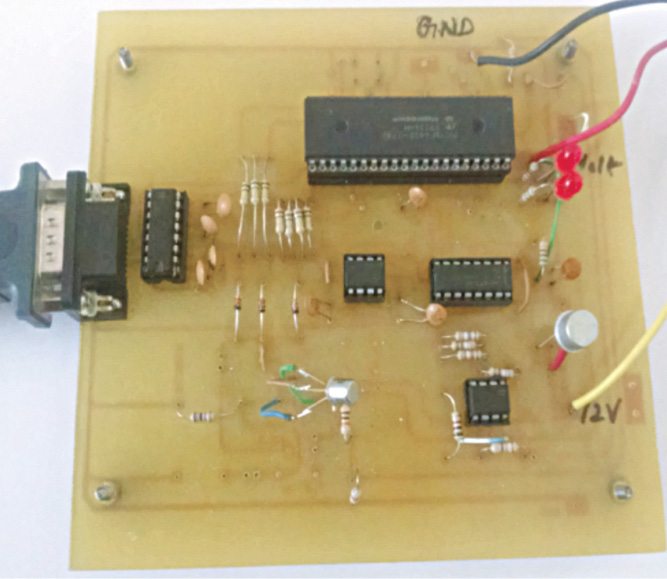

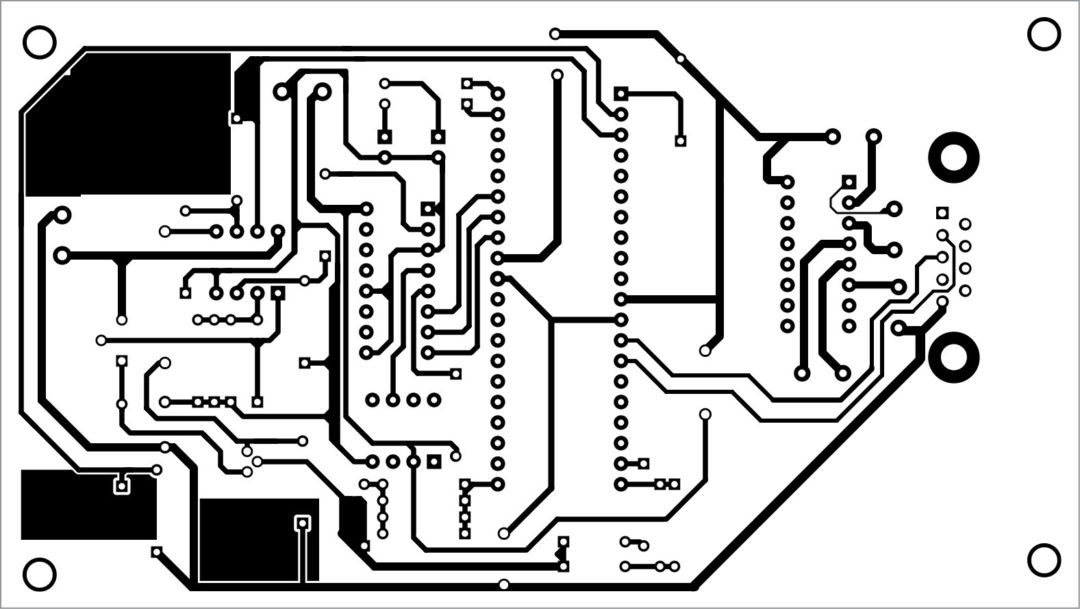

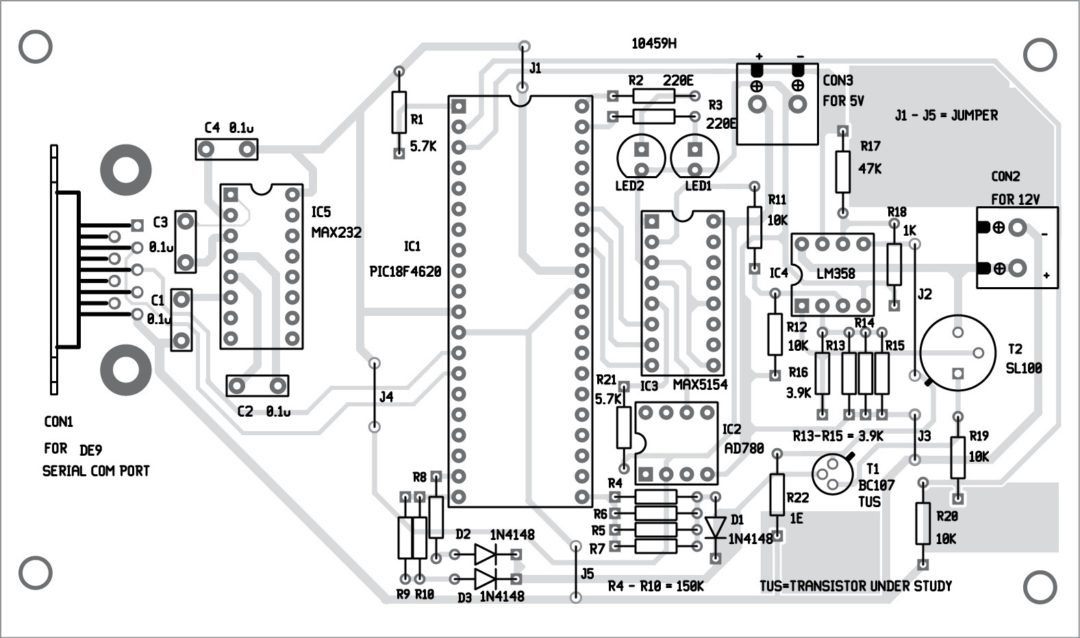

Presented here is a project for a simple transistor’s output characteristic curve-tracer program through the serial interface and PIC microcontroller using Python programming language. Output characteristic curve of a transistor is automated using Python software and serial interface. Application software for collecting the measured value and displaying it on the monitor screen is developed using Python.

Presented here is a project for a simple transistor’s output characteristic curve-tracer program through the serial interface and PIC microcontroller using Python programming language. Output characteristic curve of a transistor is automated using Python software and serial interface. Application software for collecting the measured value and displaying it on the monitor screen is developed using Python.

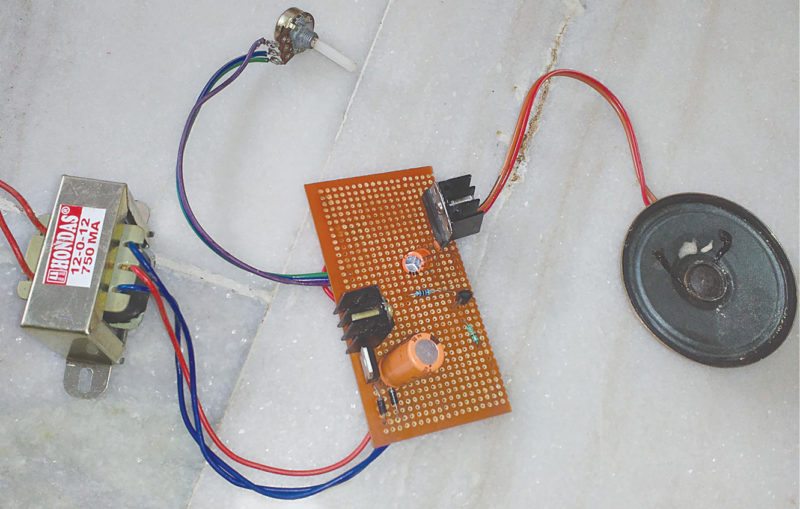

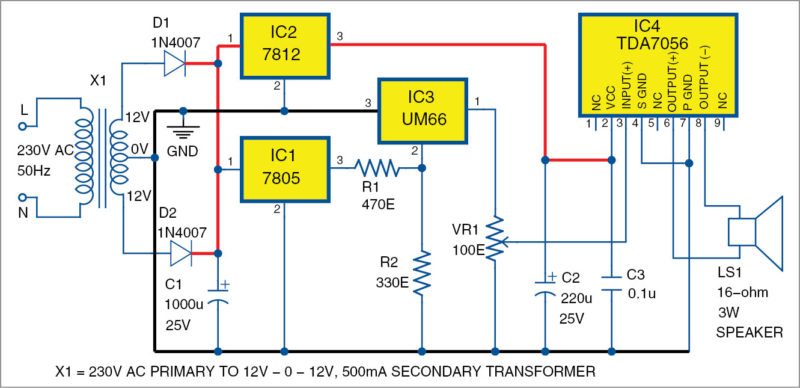

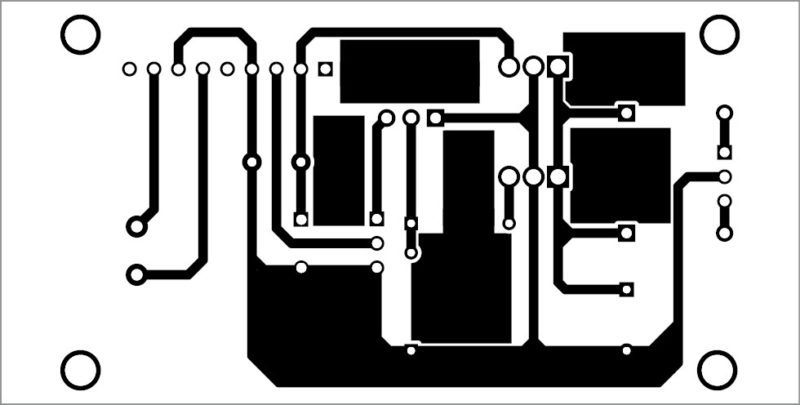

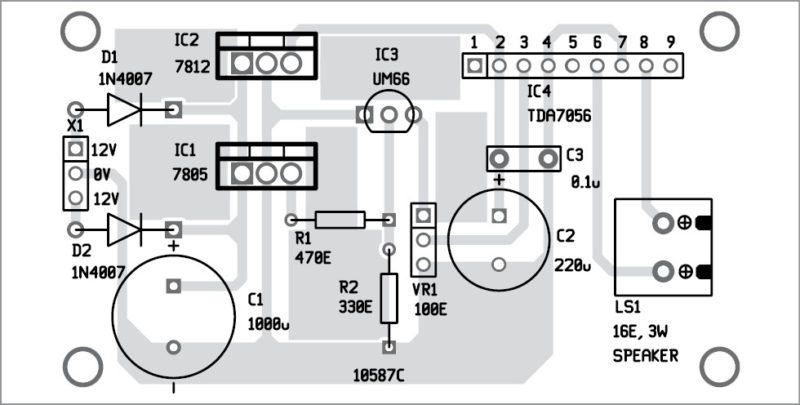

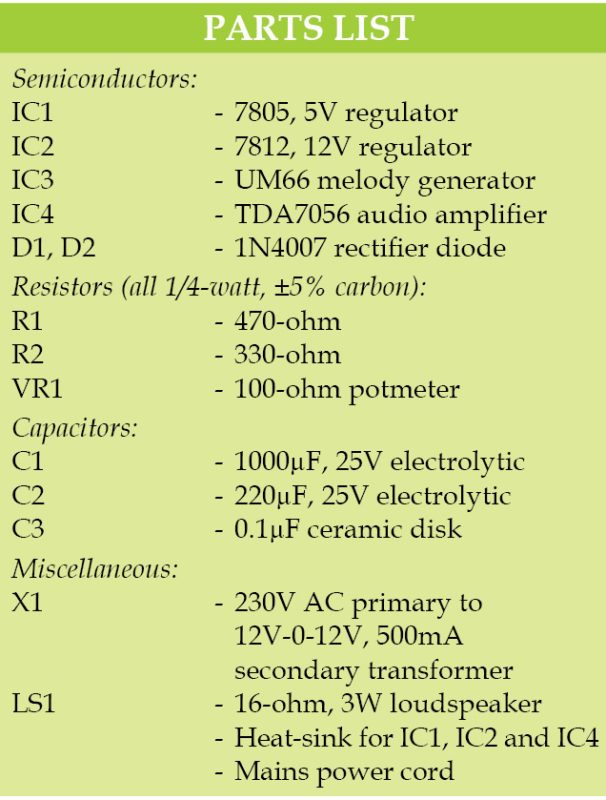

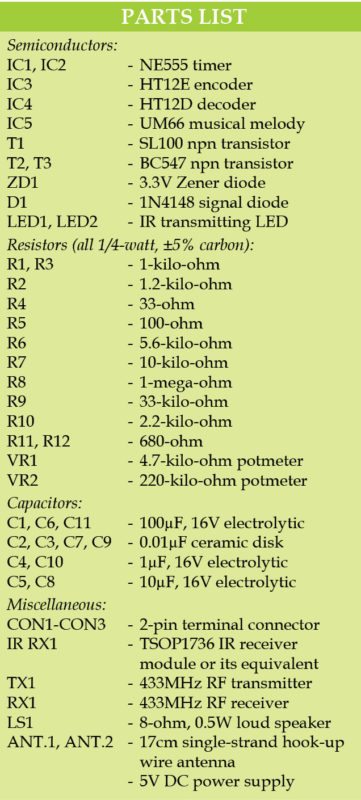

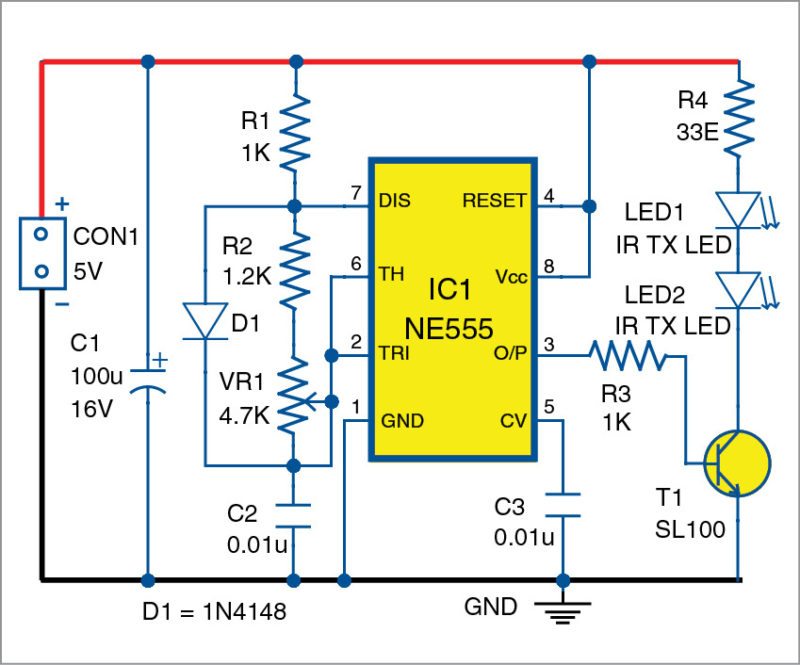

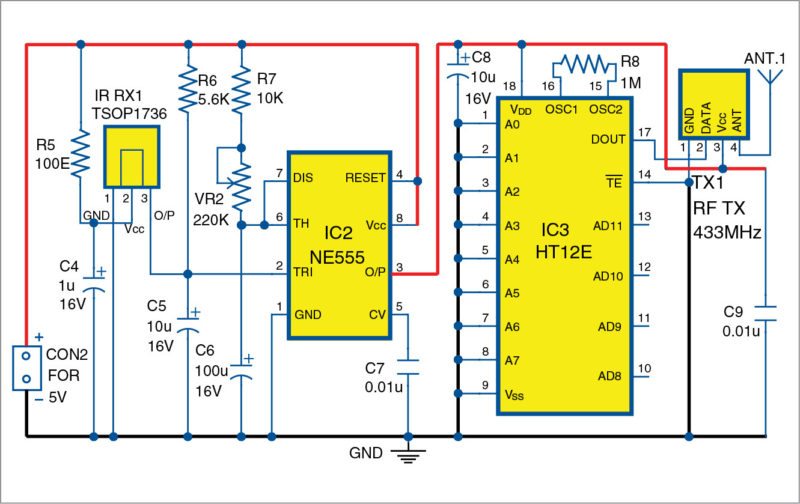

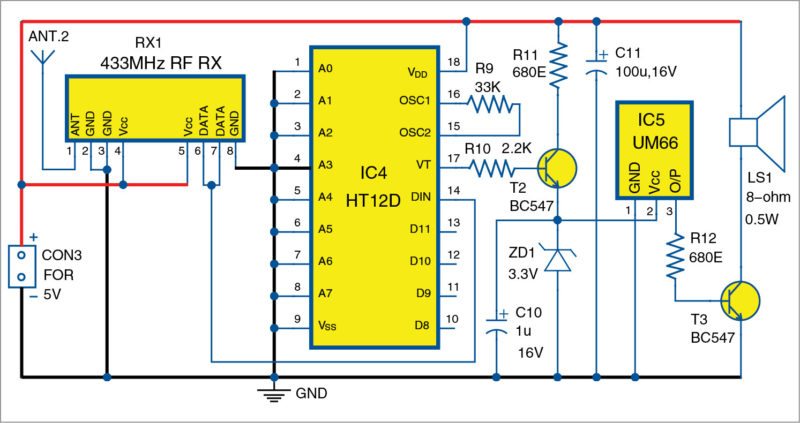

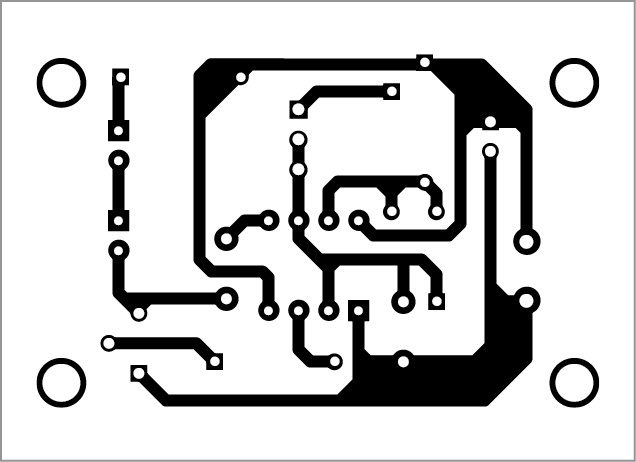

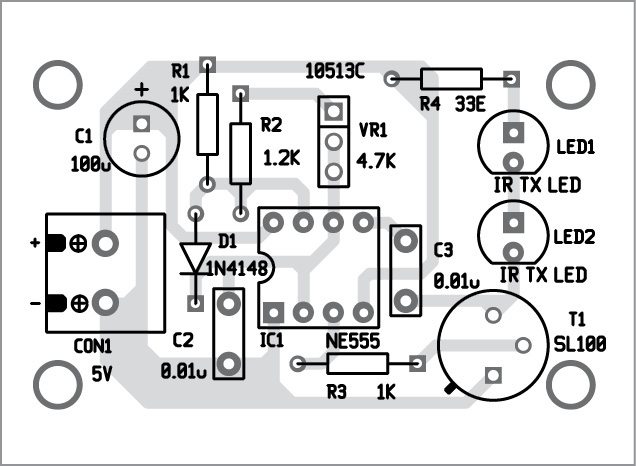

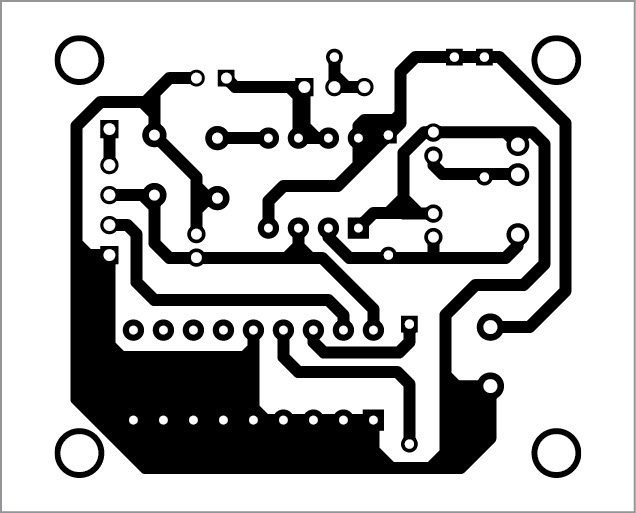

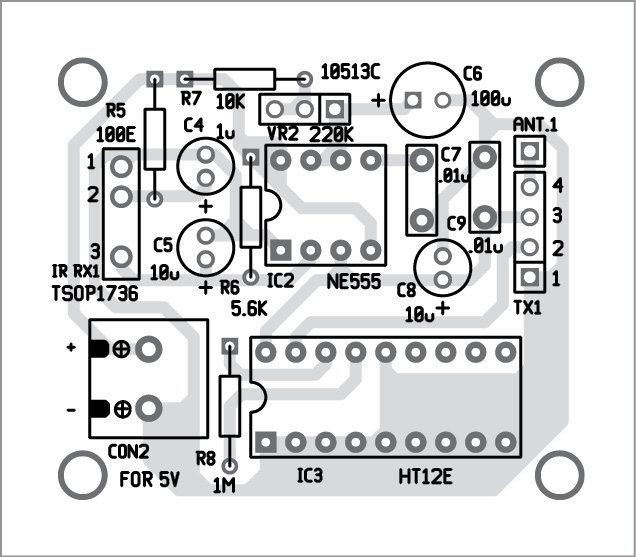

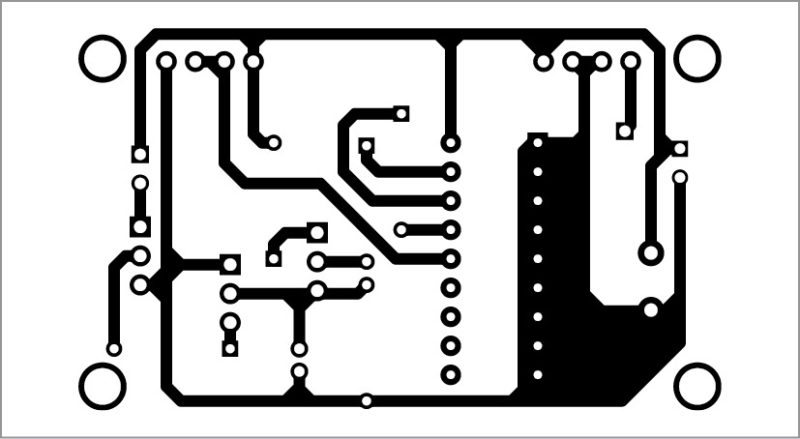

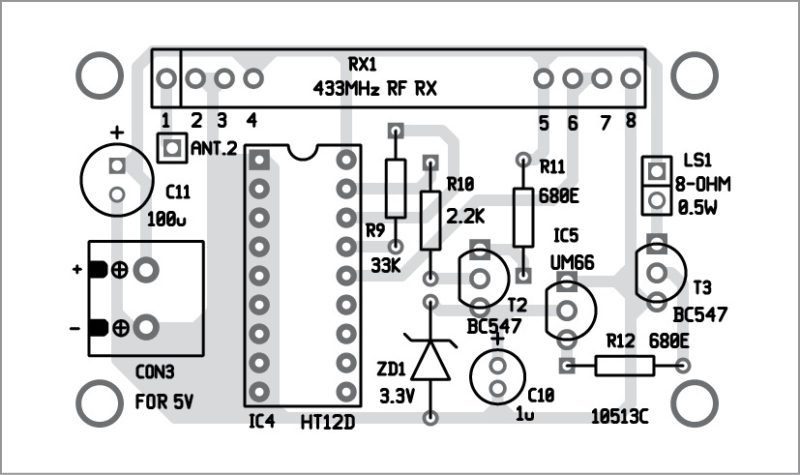

This wireless gate alarm uses infrared (IR) and 433MHz RF modules. IR transmitter unit emits 36kHz signal and is fitted on one side of the gate’s frame. IR receiver unit and RF transmitter module, along with the encoder, are fitted on the opposite side of the gate’s frame. The alarm unit is kept inside the house, and it uses 433MHz RF receiver module and musical alarm circuit.

This wireless gate alarm uses infrared (IR) and 433MHz RF modules. IR transmitter unit emits 36kHz signal and is fitted on one side of the gate’s frame. IR receiver unit and RF transmitter module, along with the encoder, are fitted on the opposite side of the gate’s frame. The alarm unit is kept inside the house, and it uses 433MHz RF receiver module and musical alarm circuit.

Mocana, a provider of critical security solutions for industrial control systems (ICS) and the Internet of Things (IoT) and Gemalto, a leader in IoT and digital security, have together announced a new partnership to bring connectivity, security and monetization to IoT deployments. The two companies will provide an end-to-end solution for IoT security lifecycle management, including interoperability of Mocana’s IoT Security Platform and Gemalto’s digital security products to protect data and digital identities across endpoint devices, gateways and clouds. Combining the companies’ respective areas of expertise makes it easier for manufacturers, enterprises and service providers to build strong security into IoT devices and critical infrastructure that are vulnerable to cyber-attacks.

Mocana, a provider of critical security solutions for industrial control systems (ICS) and the Internet of Things (IoT) and Gemalto, a leader in IoT and digital security, have together announced a new partnership to bring connectivity, security and monetization to IoT deployments. The two companies will provide an end-to-end solution for IoT security lifecycle management, including interoperability of Mocana’s IoT Security Platform and Gemalto’s digital security products to protect data and digital identities across endpoint devices, gateways and clouds. Combining the companies’ respective areas of expertise makes it easier for manufacturers, enterprises and service providers to build strong security into IoT devices and critical infrastructure that are vulnerable to cyber-attacks.

Both the SAM D5x and E5x families contain comprehensive cryptographic hardware and software support, enabling developers to incorporate security measures at a design’s inception. Hardware-based security features include a Public Key Cryptographic Controller (PUKCC) supporting Elliptic Curve Cryptography (ECC) and RSA schemes as well as an Advanced Encryption Standard (AES) cipher and Secure Hash Algorithms (SHA).

Both the SAM D5x and E5x families contain comprehensive cryptographic hardware and software support, enabling developers to incorporate security measures at a design’s inception. Hardware-based security features include a Public Key Cryptographic Controller (PUKCC) supporting Elliptic Curve Cryptography (ECC) and RSA schemes as well as an Advanced Encryption Standard (AES) cipher and Secure Hash Algorithms (SHA).