McLaren-Honda, manufacturer of premium electric racing cars, recently started using silicon-carbide (SiC) power devices in inverters and on-board chargers, which increased their efficiency by 1.7 per cent while also reducing the cooling system size by 30 per cent. Thus, a change in the power component not only made their inverter compact but also rugged for use in electric cars. Similarly, gallium-nitride (GaN) power devices increase the reliability of low-power products.

“Both SiC and GaN-based power-conversion devices are creating a difference and making the product rugged,” says Niranjan G., general manager (business development & technical marketing), ROHM Semiconductor.

Ruggedising electronic hardware: external and internal

A hardware system needs to be electrically as well as physically rugged so that it can withstand harsh environmental conditions, electrical faults, component failures, mechanical faults, etc.

![SiC and GaN market analysis (Image courtesy: www.pntpower.com)]()

Fig. 1: SiC and GaN market analysis (Image courtesy: www.pntpower.com)

For instance, for LED luminaires, designers select LED devices based on the application requirements of lumens, life-time, intensity and colour temperature. Optical component selection is also based on the application. Power supply is designed keeping in mind the desired current, voltage, power input, total harmonic distortion (THD) and power factor. Mechanical part is based on the thermal dissipation of the luminaire as a whole.

Besides, designers follow various manufacturing standards that are important from ruggedness point of view. LM79 standard is followed for LED luminaire performance test, and LM80 for LED evaluation. IPXX standards are followed for protection of LED luminaires and power supply from environmental conditions such as air, water, dust, physical contact and accidental contacts. IEC, EC, UL and BEE standards pertain to the quality of a hardware product.

The hardware includes the PCB and components on the PCB. Be it an analogue solution, power solution, sensing solution or mobile solution, hardware must be well-built and rugged.

Analogue and power solutions

There have been industrial upgrades in the quality of the PCB, power components and their hardware applications at electrical or physical level.

PCB and improved substrate

The PCB is an essential element of a hardware as it provides the base or the platform to the circuitry. The PCB material is chosen based on the type of application. For instance, as a small power supply with less input and output current will dissipate very less heat, it can be built on an FR4-based PCB, which costs very less.

Hrishikesh Kamat, CEO of Shalaka Connected Devices, says, “Multilayer boards have been prepped up to 256 layers by tech giants.”

As electronic devices shrink, PCBs are becoming smaller and multilayer to support connectivity with several components at a time. Complexity of the circuitry is increasing and the technology is getting sophisticated. The average thickness of the PCB ranges between 0.5mm and 0.7mm, which, technology experts believe, will decrease further to 0.4mm or less. This will open up new possibilities in the wearables domain.

Traditionally, PCB prepregs have been fibreglass or epoxy, but now substrates are available in several other materials too, such as resin-coated copper, resin-coated film and liquid-crystal film. These prepregs maintain the signal integrity of a circuit and high-end processing at low costs.

Thus, improved PCB substrate and reduced PCB thickness ensure high signal integrity and low output losses, resulting in a reliable and rugged hardware.

Smaller, stronger, faster components

Silicon carbide is becoming the industry-leading technology in power conversion, contributing to the eco-friendly environment. ‘Trench-structure’ design contributes to the long-term reliability of components. Nowadays, these trench-structure MOS devices are acting as alternatives to relays in automobiles (especially electric vehicles) due to their high current handling capability. Their other field applications include industrial automation equipment, solar power inverters, digital power supplies of large-scale servers in data centres and home appliances such as air-conditioners.

![Ruggedising Electronic Hardware]()

For low-power and medium-power applications, trench-structure devices provide many advantages:

1. Structural change lowers the drain-to-source resistance (RDS ON) and thus heat dissipation, making the end product efficient

2. Breakdown voltage and switching frequencies of trench-structure MOSFETs and other components using SiC are generally higher than conventional FETs

3. Low on-resistance, high breakdown voltage, high current and high frequencies enable a compact and efficient cooling system

4. The compact size of the component helps in reducing the size and the cost of the PCB

“Thus, silicon carbide reduces the overall system costs and helps in energy conservation by making efficient end-products,” says Niranjan.

![Trench power MOS in SiC device (Image courtesy: patentimages.storage.googleapis.com)]()

Fig. 2: Trench power MOS in SiC device (Image courtesy: patentimages.storage.googleapis.com)

Chip resistor—no more laser cuts for accurate value

Niranjan says, “Thermo-mechanical stress causes resistor failure, so manufacturers are coming up with a techno-logy that allows solder application on the lateral side of the resistor chip.”

Chip resistors’ solder area on their lateral side assists them to sit well on copper pads, avoiding short-circuit and open-circuit faults and breakage due to thermal and mechanical stresses. This helps the resistors to remain cracks-free for a long term.

As far as the manufacturing of chip resistors is concerned, earlier laser cuts were carried out to adjust the resistor value. With that method, usually, the resistor value did not exactly match the customer requirement. Now the practice of laser cuts in resistors has been discontinued, which allows resistor values according to specifications.

The post Ruggedise the Hardware: Increase Its Life appeared first on Electronics For You.

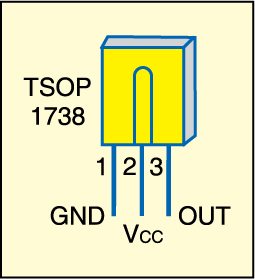

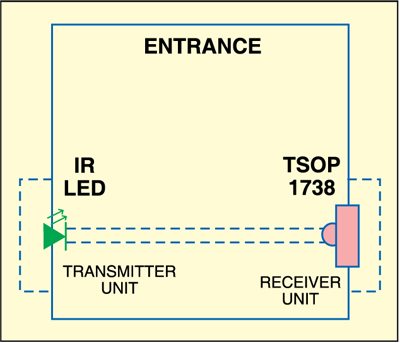

This IR based light control circuit turns on the lights at the portico, car parking or other areas when a motorbike or car enters through the gate to cross the sensing area. It can also be used as an electronic watchdog for your house, by activating an alarm simultaneously.

This IR based light control circuit turns on the lights at the portico, car parking or other areas when a motorbike or car enters through the gate to cross the sensing area. It can also be used as an electronic watchdog for your house, by activating an alarm simultaneously.

Most computer UPS have only 230V output and no USB output. Presented here is a USB power circuit that gives 5V USB output using the 12V, 7Ah UPS battery fitted inside a UPS. With this circuit you can power USB gadgets directly from a UPS without turning on the PC. This circuit can also be used to power development boards like Arduino and Raspberry Pi.

Most computer UPS have only 230V output and no USB output. Presented here is a USB power circuit that gives 5V USB output using the 12V, 7Ah UPS battery fitted inside a UPS. With this circuit you can power USB gadgets directly from a UPS without turning on the PC. This circuit can also be used to power development boards like Arduino and Raspberry Pi.

Bangalore – January 10, 2018 – Analog Devices, Inc. has announced the Power by Linear LTC7821, an industry first hybrid step-down synchronous controller that merges a switched capacitor circuit with a synchronous step-down controller, enabling up to a 50% reduction in DC/DC converter solution size compared to traditional step-down solutions. This improvement is enabled by a 3 times higher switching frequency without compromising efficiency. Alternatively, when operating at the same frequency, a LTC7821-based solution can provide up to 3% higher efficiency. Other benefits include low EMI and reduced MOSFET stress due to a soft-switched front end, ideal for next generation non-isolated intermediate bus applications in power distribution, datacom and telecom as well as emerging 48V automotive systems.

Bangalore – January 10, 2018 – Analog Devices, Inc. has announced the Power by Linear LTC7821, an industry first hybrid step-down synchronous controller that merges a switched capacitor circuit with a synchronous step-down controller, enabling up to a 50% reduction in DC/DC converter solution size compared to traditional step-down solutions. This improvement is enabled by a 3 times higher switching frequency without compromising efficiency. Alternatively, when operating at the same frequency, a LTC7821-based solution can provide up to 3% higher efficiency. Other benefits include low EMI and reduced MOSFET stress due to a soft-switched front end, ideal for next generation non-isolated intermediate bus applications in power distribution, datacom and telecom as well as emerging 48V automotive systems.